Customized shape memory alloys using ultrasound?

Scientists from the Institute of Materials Engineering, Department of Metallic Materials, led by Prof. Dr.-Ing. Thomas Niendorf and the Department of Separating and Joining Manufacturing Processes, headed by Prof. Dr.-Ing. Prof. h.c. Stefan Böhm, are investigating the influence of ultrasound on so-called cobalt-nickel-gallium high-temperature shape memory alloys during additive manufacturing (3D printing) in a project funded by the DFG. The aim of the project is to directly tailor the shape memory properties, as it is already known that ultrasound sets the molten material in motion and could enable targeted control of solidification.

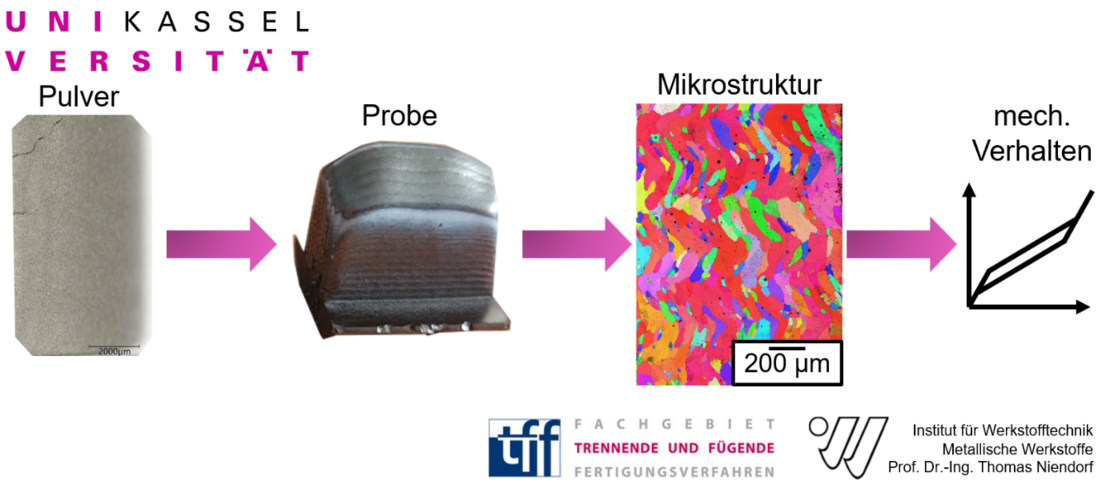

High-temperature shape memory alloys are particularly suitable as material- and cost-efficient sensors and actuators in high-temperature applications. One attractive alloy system is the cobalt-nickel-gallium high-temperature shape memory alloy (Co-Ni-Ga-HT-FGL for short), which is characterized by comparatively low alloying costs and very good functional properties up to temperatures of 500°C. Numerous preliminary studies and publications in the fields of metallic materials and cutting and joining manufacturing processes have already shown that this alloy system is easy to process and can produce suitable microstructures. In addition, it is already known from other alloy systems that ultrasonic waves can produce a very different microstructure during additive processing and pave the way for three-dimensionally graded structures.

Image: tff

Image: tffScientists from the Institute of Materials Engineering, Department of Metallic Materials, led by Prof. Dr.-Ing. Thomas Niendorf and the Department of Separating and Joining Manufacturing Processes, headed by Prof. Dr.-Ing. Prof. h.c. Stefan Böhm, are investigating the influence of ultrasound on so-called cobalt-nickel-gallium high-temperature shape memory alloys during additive manufacturing (3D printing) in a project funded by the DFG. The aim of the project is to directly tailor the shape memory properties, as it is already known that ultrasound sets the molten material in motion and could enable targeted control of solidification.

High-temperature shape memory alloys are particularly suitable as material- and cost-efficient sensors and actuators in high-temperature applications. One attractive alloy system is the cobalt-nickel-gallium high-temperature shape memory alloy (Co-Ni-Ga-HT-FGL for short), which is characterized by comparatively low alloying costs and very good functional properties up to temperatures of 500°C. Numerous preliminary studies and publications in the fields of metallic materials and cutting and joining manufacturing processes have already shown that this alloy system is easy to process and can produce suitable microstructures. In addition, it is already known from other alloy systems that ultrasonic waves can produce a very different microstructure during additive processing and pave the way for three-dimensionally graded structures.

Image: IfW

Image: IfWIm Rahmen des von April 2023 bis März 2026 laufenden Projekts „Funktional gradierte Co-Ni-Ga- Hochtemperaturformgedächtnislegierungen hergestellt mittels ultraschallangeregtem 3D-LaserPulver-Auftragschweißen“, das mit rund 700.000 Euro von der Deutschen Forschungsgemeinschaft DFG gefördert wird, soll das Laser-Pulver-Auftragsschweißen dazu genutzt werden, bisherige Limitierungen in der Verarbeitung der Legierung zu überwinden und durch Ultraschall gezielte Mikrostrukturen in gewünschten Bereichen einzustellen, sodass ein Maßschneidern der vorliegenden FGLs möglich wird.

Formgedächtnislegierungen gehören zu den Forschungsschwerpunkten von Prof. Dr.-Ing. Thomas Niendorf, Leiter des Fachgebiets Metallische Werkstoffe am Institut für Werkstofftechnik. FGLs sind Legierungssysteme, welche eine reversible diffusionslose Phasenumwandlung (martensitische Umwandlung) meist unter Aufbringung einer Spannung oder Temperaturänderung zeigen. Nach einer Verformung kehren sie bei Erwärmung in ihre alte Form zurück, was ihnen ihren Namen verleiht. Anwendungsgebiete sind beispielsweise Verbindungselemente für Rohre, Stents und Zahnspangendrähte in der Medizintechnik oder Aktoren in der Automobil-, Luft- und Raumfahrttechnik.

Das Projekt wird im Rahmen des Forschungsclusters „BiTWerk – Biologische Transformation technischer Werkstoffe“ durchgeführt.