Next generation of high-temperature shape memory alloys based on titanium-tantalum realized via additive manufacturing

Image: IfW

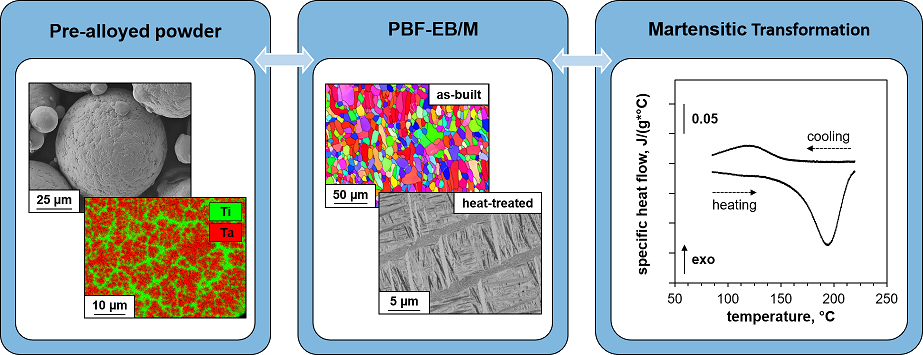

Image: IfWHigh-temperature shape memory alloys (HT-FGL) based on titanium-tantalum (Ti-Ta) are promising candidates for actuator applications at elevated temperatures. Researchers from the Institute of Materials Engineering, in collaboration with partners from Taniobis GmbH in Germany and the RMIT Centre for Additive Manufacturing in Australia, have investigated these alloys, which belong to the so-called smart materials, as part of a new study. The study demonstrates the microstructure and functional properties of an additively manufactured Ti-30Ta (at.%) alloy. For the first time, this alloy system was successfully processed using selective electron beam melting (PBF-EB/M). Structures with a density of over 99.9% and an isotropic microstructure were realized. After a heat treatment downstream of the manufacturing process, a reversible martensitic phase transformation at well over 100 °C was also demonstrated.

The results have now been published in the article "Electron beam powder bed fusion of Ti-30Ta high-temperature shape memory alloy: microstructure and phase transformation behavior".

The study was funded by the Alexander von Humboldt Foundation and is part of the BiTWerk project funded by the University of Kassel.