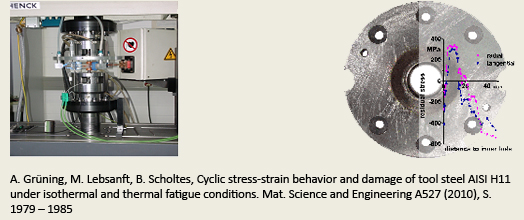

| Prof. Dr.-Ing. habil. Berthold Scholtes Lehrstuhl für metallische Werkstoffe, Institut für Werkstofftechnik, Kassel Institute of Materials Engineering - Metallic Materials The research activities are focussed on the determination and assessment of microstructure-properties-relationships of metallic materials. Special areas of interest are plasticity and fracture, fa-tigue, corrosion fatigue, thermal fatigue and crack propagation. In this context also the determination of residual stress states and the evaluation of their origins and consequences play a key role. Special laboratories exist for stress analysis by mechanical and diffraction methods and for fatigue tests under ambient as well as high temperature and corrosive conditions. Within the frame of the Collaborative Research Center TRR 30, the formation of residual stress states in tools and components during hot metal forming is analyzed. In this context, thermal fatigue tests of tool steels are carried out to simulate the local materials behavior. Fig. 1(left) shows equipment used for such tests. In Fig. 1(right) a characteristic residual stress distribution in a tool used for hot metal forming of flange shafts is shown. In addition, all other standard test facilities as well as microscopic methods are available.

Particular attention is given to near surface materials regions, affected by manufacturing operations and their consequences on the mechanical behavior of components. In this context, traditional as well as new and innovative mechanical surface treatments as well as combinations of mechanical and thermal treatments are investigated. Fig. 2 (left) shows residual stress distributions measured after different thermo-mechanical surface treatments and their consequences on fatigue life in bending fatigue tests (right).

» Back to Who is Who |

|

|