Research

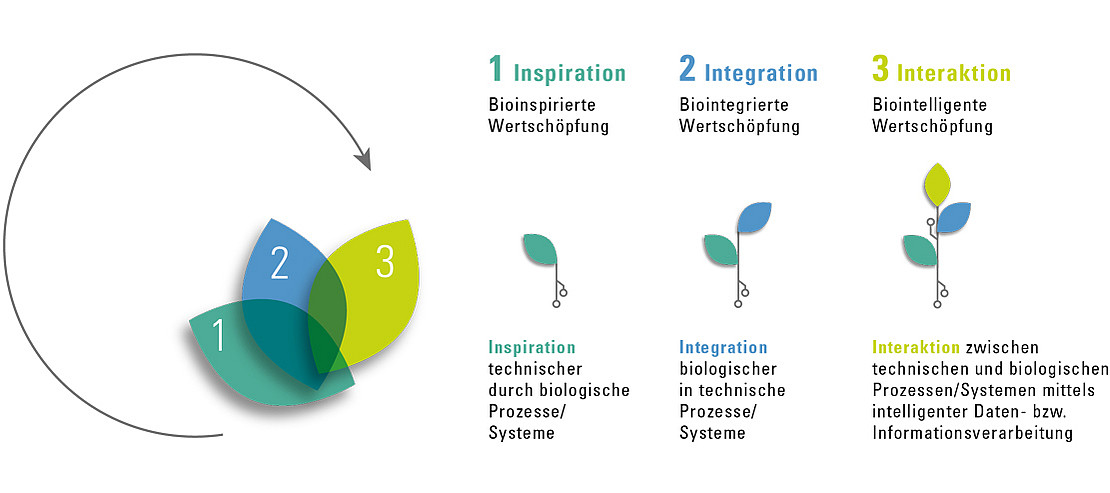

Biological transformation

BiTWerk approaches the challenges of biological transformation via two thematic fields: "Biological transformation via novel molecular, micro- and nanoparticular systems" and "Biological transformation via robust manufacturing processes for the realization of granular and graded structures based on monolithic materials".

The finite nature of many resources, rising raw material prices and extraction costs, as well as environmental and social impacts are just some of the problems that arise in connection with the extraction, processing and disposal of raw materials. The biologization of technical materials is intended to help overcome these challenges. The key to achieving this goal is maximum functional integration combined with sustainable material design.

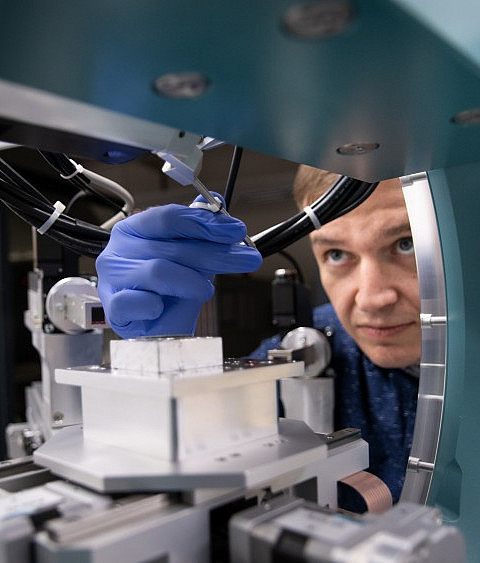

Image: Paavo Blafield

Image: Paavo BlafieldWe assume that:

- the integration of as many functions as possible through molecular, nano and micro components in materials enables completely new material or system properties and functions. As in nature, the functions are an integral part of the materials and the components made from them. The production of many individual components with individual functions is avoided, thus reducing the ecological footprint.

- the consistent use of digital twins improves the understanding of materials and accelerates the development of both new material classes and functions. In particular, the structural characteristics that are relevant across several scales can only be captured with modern data processing.

- Different classes of properties (e.g. magnetic, mechanical, optical, electrical) must be realized within a material and component and not separately from each other. Methods for modeling and simulation must therefore also enable the coupling of different model classes to map these complex relationships.

- In the long term, it will be possible to transfer particulate functional systems and their carrier materials into a material cycle. In this material cycle, similar to a biological material cycle, the functions created on the basis of many individual formulation components should first be used and the formulation then broken down again in order to make the starting raw materials available for a further utilization phase.

In addition to functional integration, we are also looking at the use of "simple" materials, i.e. monolithic materials (materials with the same stoichiometry / chemical composition), which can be represented with locally different properties and functions solely through differences in their local nano- and microstructural composition ("gradient materials"). Regardless of the intended solution, this requires a profound understanding of the relationships between the internal structure (the microstructure) of materials, their targeted modification and the resulting properties over the entire life cycle.

Image: Paavo Blafield

Image: Paavo BlafieldFollowing this approach, we assume that:

- by using suitable monolithic materials, highly functional components and structures can already be realized during the manufacturing process, e.g. via additive manufacturing, and/or suitable post-treatment of the surface areas. The use of smart materials in particular allows large variances in the achievable local properties.

- surface post-treatment using ultrashort pulse laser technology allows previously unrealizable surface conditions to be achieved. With knowledge of all relevant influencing variables, e.g. described using grey box models, the grading degrees of the edge zone can be specifically adjusted over a wide range.

- the granularity of the structural information of these graded materials can be recorded across scales using modern methods of materials analysis and can be optimally mapped using suitable models, based on physics and data, and made usable in the sense of digital twins.

- the information on the granularity of the structural information can be used to identify concepts for the design of graded structures across main material groups, which can be directly implemented using additive manufacturing processes, among other things.